Contact Us | Careers

-

Rua do Bom Jesus, n° 207 |

Recife-PE Brazil - Tel: +55 81 2128-8181

- Email: eolica@eolica.com.br

- @eolicatec

CMS | PMS | App

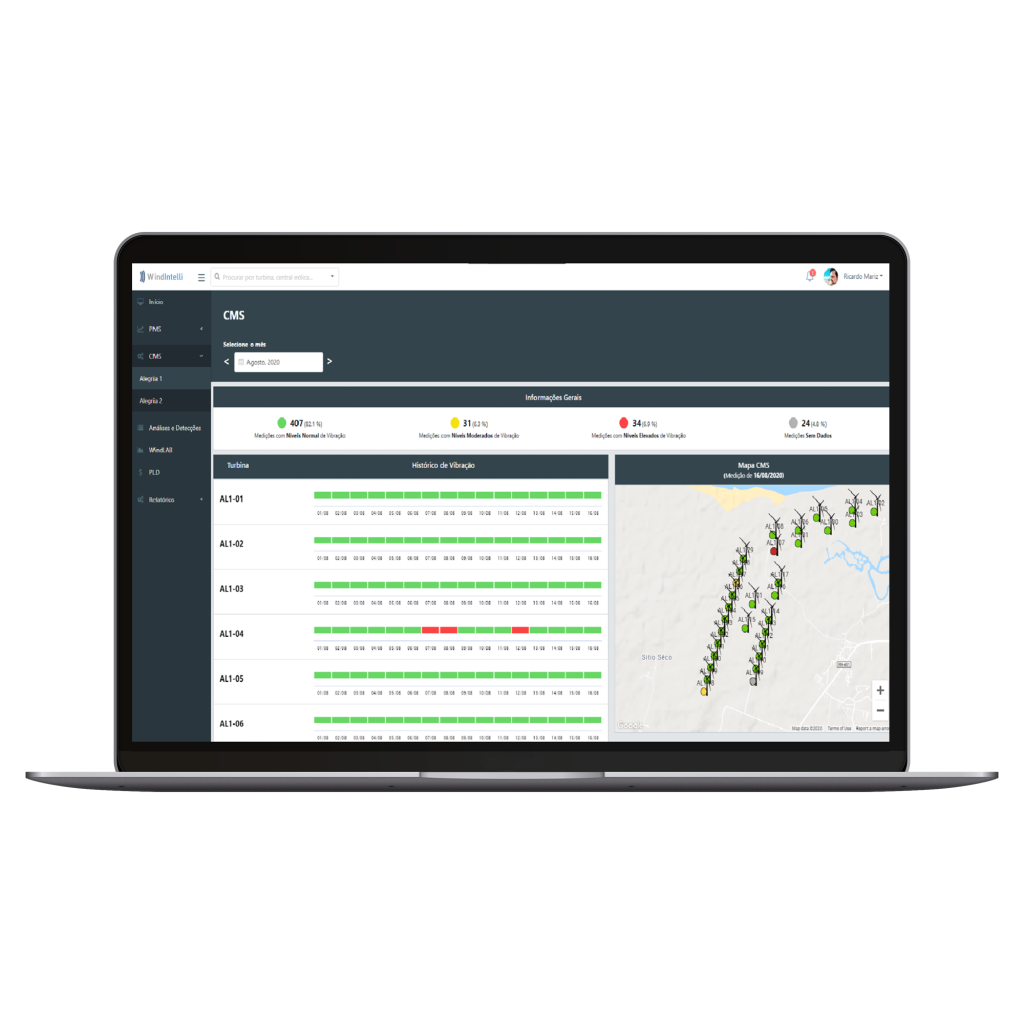

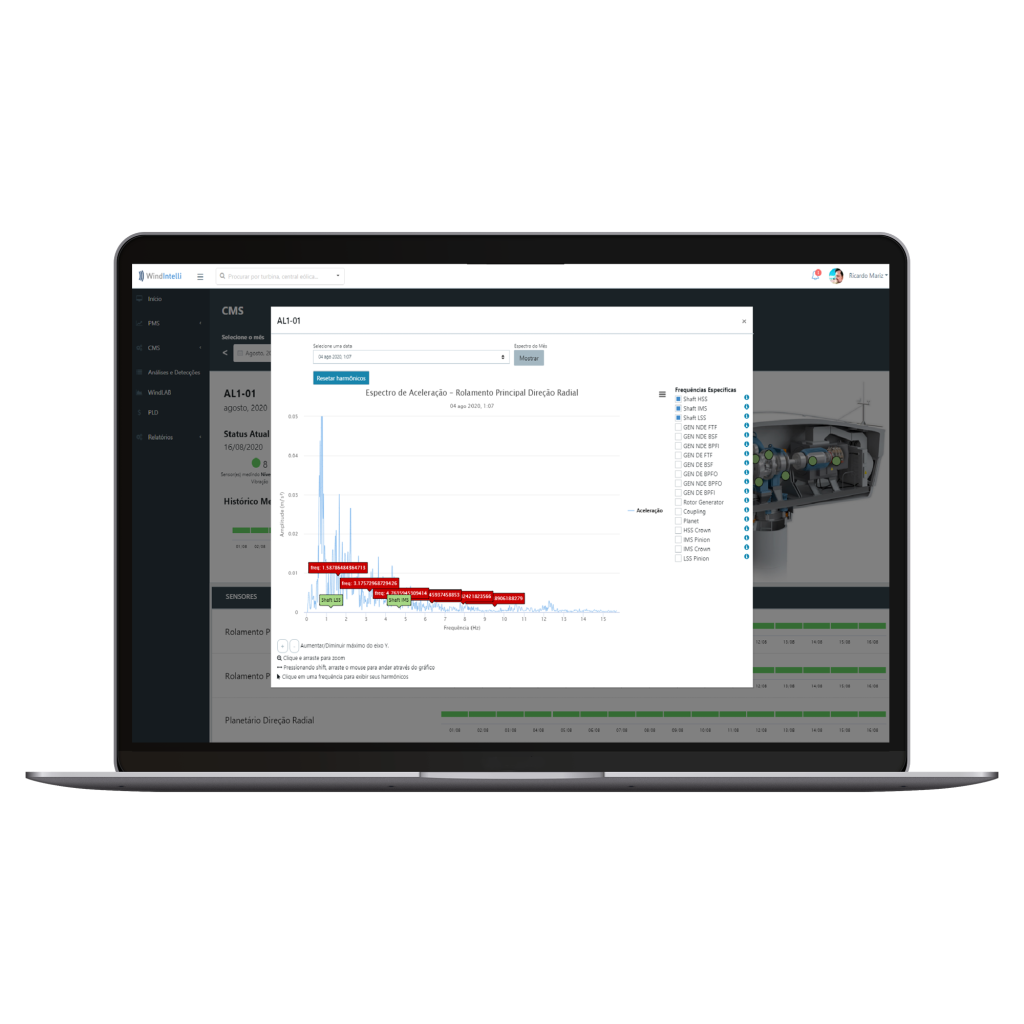

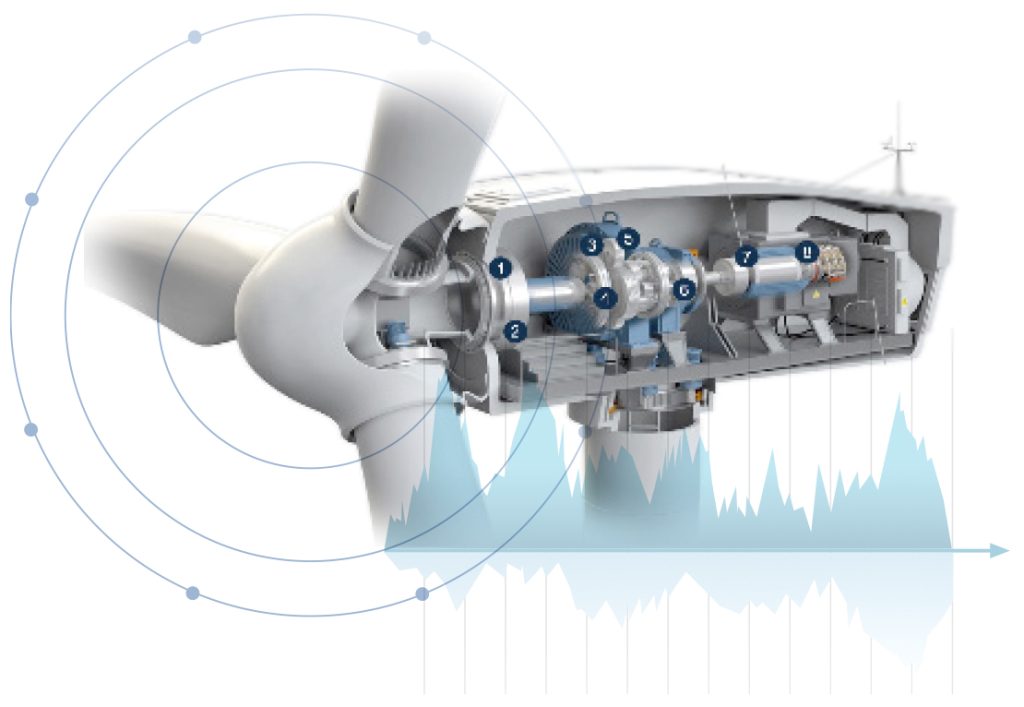

Eólica Tecnologia has a Vibration-based Condition Monitoring System (CMS) on all wind turbines. The targets of the system are reduction of maintenance costs, increase of availability, avoidance of unplanned downtimes, improvement of quality & reliability and extend wind turbine’s lifetime.

Wind farms are unlike conventional power stations, the turbines are exposed to harsh weather conditions, including severe winds, high temperature, lightning and thunderstorms. Due to these external operational conditions, the wind turbines suffer constantly intense mechanical stress with a highly variable operation conditions (speed, load, etc.). Therefore, a high degree of maintenance is required to provide a safe, cost-effective and reliable power output.

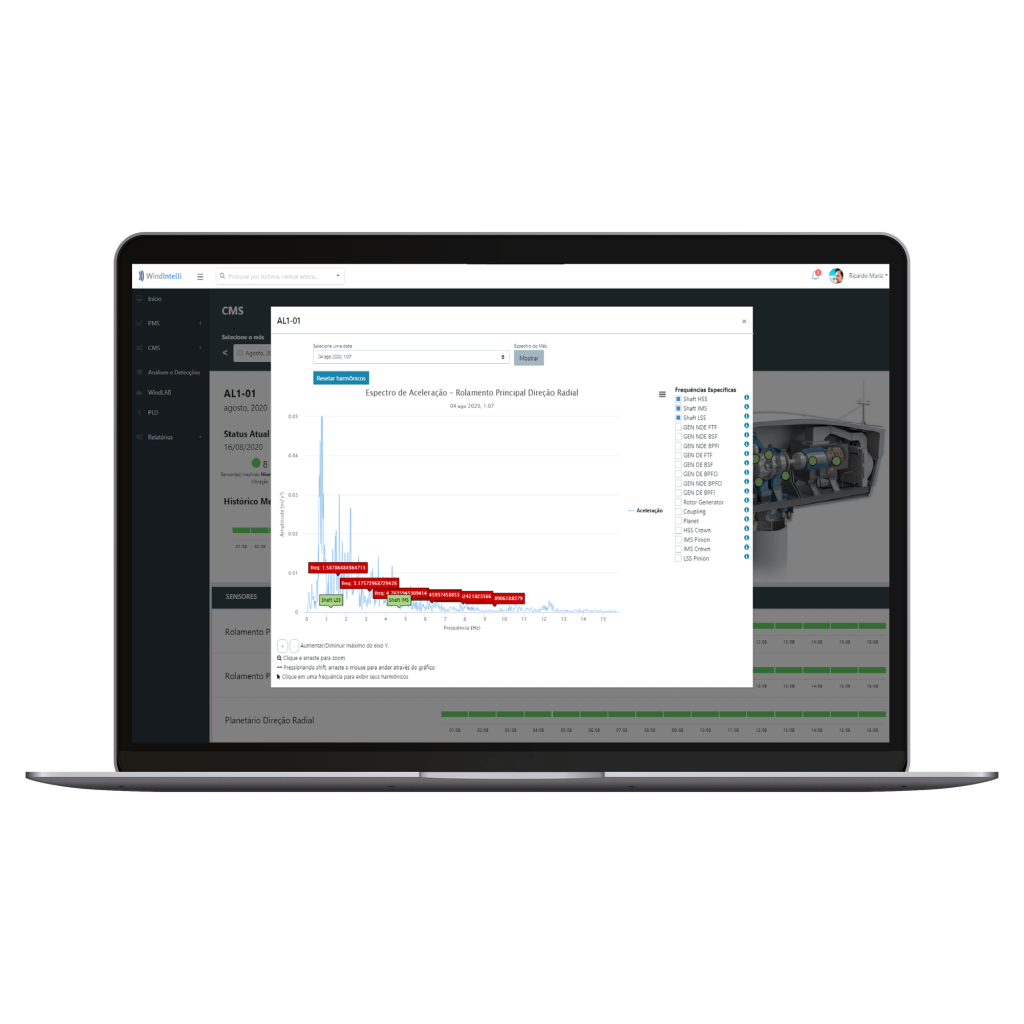

Futhermore, Eólica Tecnologia has developed its own online system to treat and analyze automatically a large database from specific vibration data for all main components of the wind turbine. It works in three main steps: data acquisition using 8 sensors per turbine, signal processing/analysis with various techniques, and daily tracking/diagnosis. The system is also capable of generating reports and alarms identifying the fault and its location, maximizing reliability of Eólica Tecnologia’s wind farms.

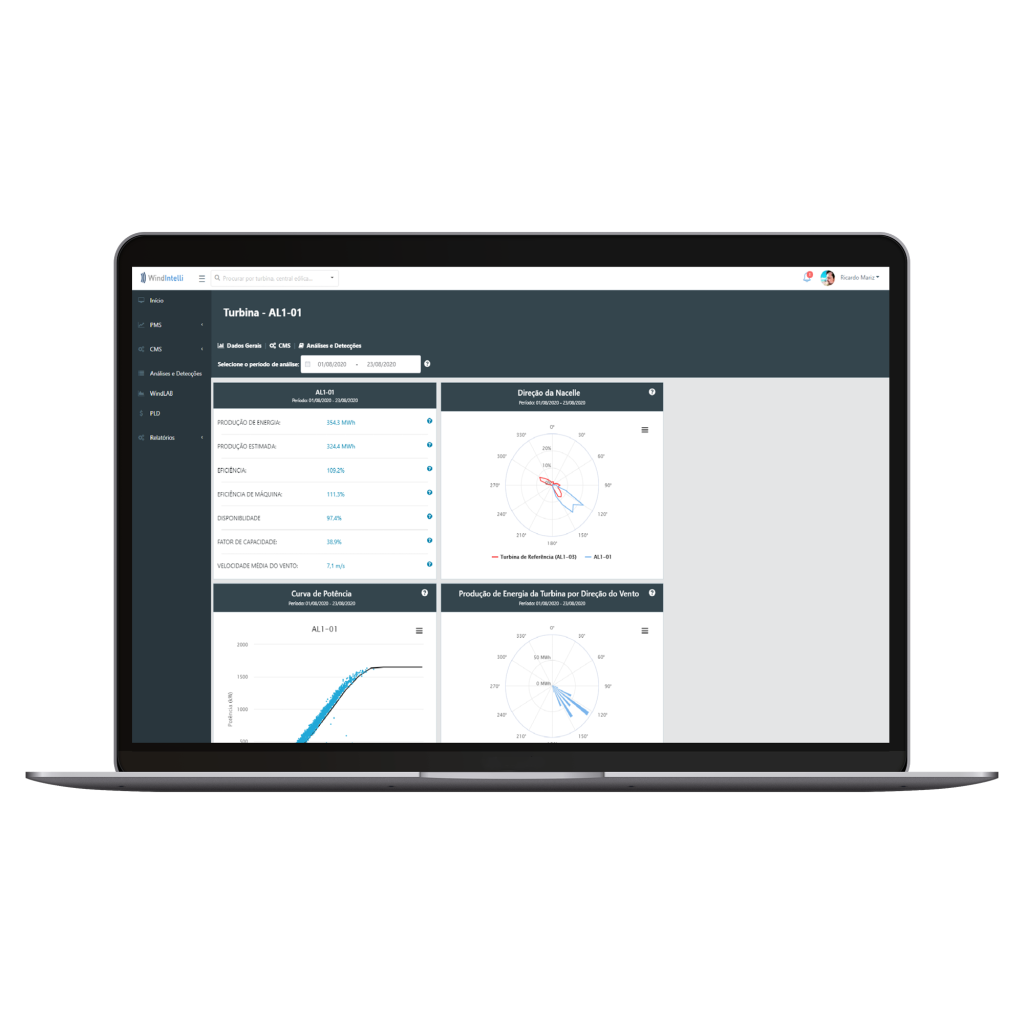

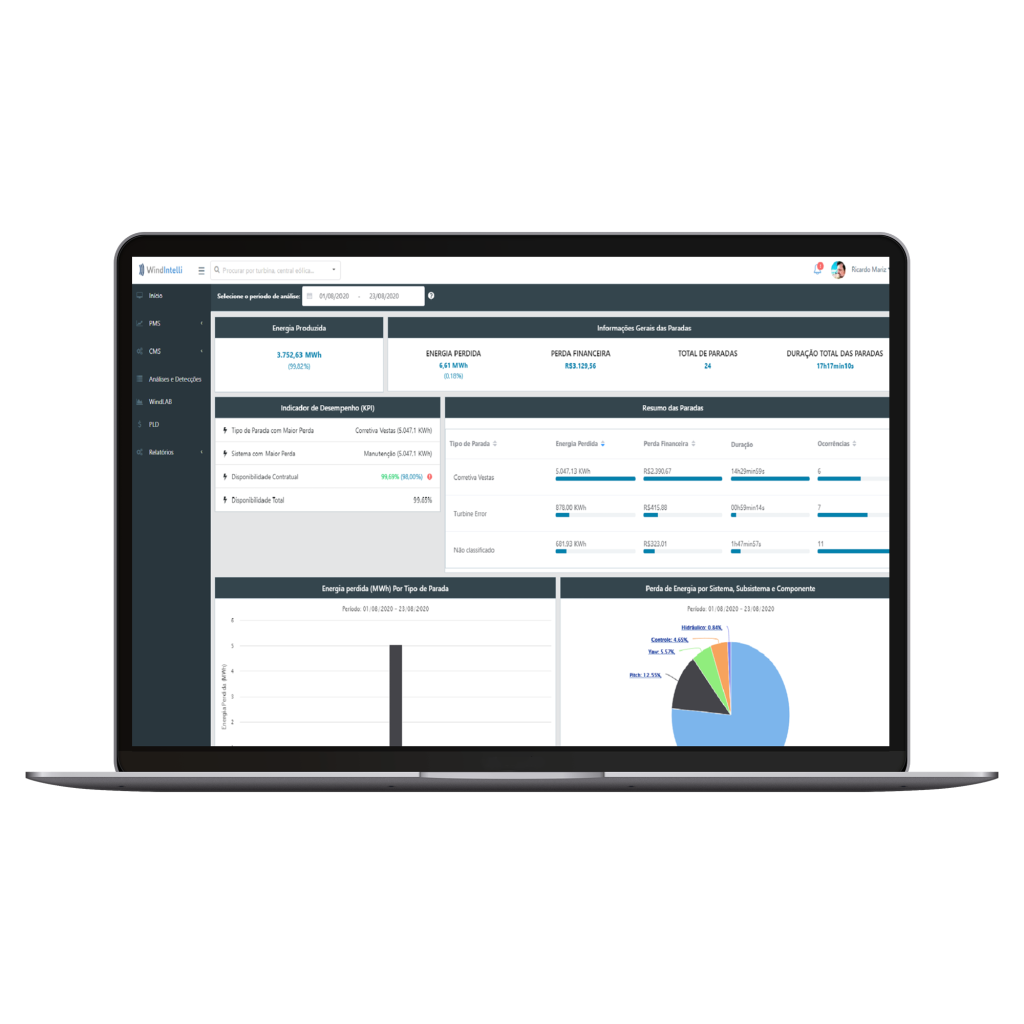

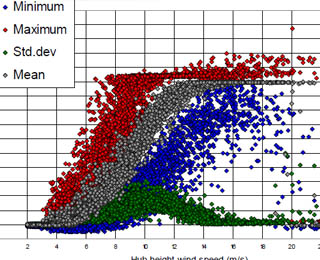

Eólica Tecnologia developed its own Performance Monitoring System (PMS) to optimize the production and reduce O&M costs of its own wind farms.

Maintenance contracts often include availability as its key performance indicator. A drawback to this approach is that it does not reflect how well the wind turbine performs. It is common to rely almost exclusively in the intuition of the wind farm operator to elaborate the maintenance planning. In reality, plenty of factors (such as the expected production, wind turbine failure, etc.) often have a negative effect in the availability of the wind farm and additional maintenance costs occurs.

Eólica Tecnologia developed the Performance Monitoring System (PMS) as an effort to optimize the production and reduce O&M costs of its own wind farms. Data from the Supervisory Control and Data Acquisition (SCADA) system (which records every possible operational characteristic of the wind turbines) is used as input to the performance monitoring solution. The data analysis of our PMS system is able to capture the true state of each wind turbine and detect performance issues, which in turn are readily informed to O&M manager that ensures their correction.

Eólica Tecnologia developed an online platform with automatic fault detection and diagnosis capabilities.

The user can manage multiple wind farms worldwide and access anywhere on any device.